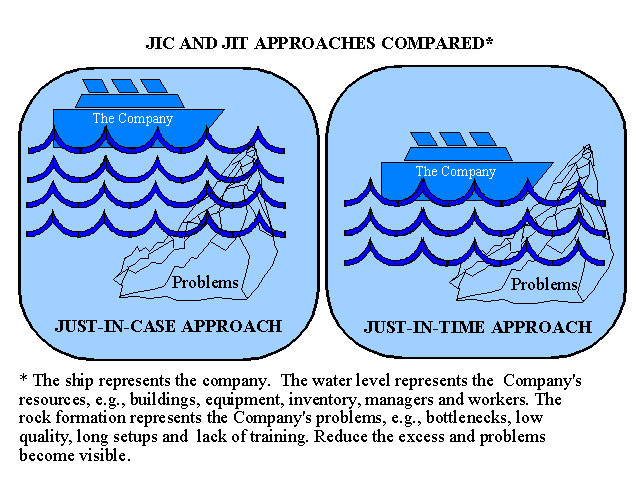

There are two opposing strategies to inventory management – just in case and just in time. Just in time inventory management keeps inventories low while just in case keeps inventories high. Each inventory control system has its place and depends on the requirements of your company.

Inventory Supply Management

An effective inventory management strategy will deliver goods efficiently and on time to customers. Until recently, companies have favored just in time inventory management. However, this model of managing stock levels is vulnerable to shortages and overstocking. To combat multiple disruptions to their supply channels many companies have adopted the just in case system.

Both inventory control systems have their advantages and disadvantages. Your supply chain requirements determine what type of inventory control system is best for your company, including a combination of both systems.

Just in Case Inventory Management

In the just in case inventory management strategy, companies maintain high levels of inventory. If highly accurate demand forecasting is not a major consideration to your business, then a just in case system is right for you. By having high stock levels, your company can meet huge customer orders and withstand disruptions. Large stock inventories ensure that your supply chain is robust and your company can better withstand disruptions that include bad weather, strikes, power failure, increased customer orders, fuel, transport, and supplier reliability.

In the just in case inventory management strategy, companies maintain high levels of inventory. If highly accurate demand forecasting is not a major consideration to your business, then a just in case system is right for you. By having high stock levels, your company can meet huge customer orders and withstand disruptions. Large stock inventories ensure that your supply chain is robust and your company can better withstand disruptions that include bad weather, strikes, power failure, increased customer orders, fuel, transport, and supplier reliability.

The main disadvantage with the just in case system is that capital is tied up in inventory, which could otherwise be put to better use, for marketing, planning, etc.

To offset costs and to match supply with demand, companies have moved closer to their customers, reducing fuel usage, delivery times and other transport costs. Regional distribution centers also shorten the time it takes for customers receive their goods.

Just in Time Inventory Management

In the just in time inventory management strategy, low inventories are kept. Parts orders, components and stock are ordered just in time, to be processed and shipped to fill customer orders. With the just in time strategy there is very little inventory kept on hand, which in turn frees up capital to be more efficiently employed elsewhere in a company.

This inventory control system is highly effective if your company can accurately forecast demand. Bad weather, traffic accidents, strikes, terrorism, and parts shortages are some of the disruptions that can detrimentally affect your supply chain and your company.

Finding the Optimum Inventory Management Strategy

A company may find that a single inventory system on its own will not work effectively. Most companies strive to strike a balance between these two inventory management systems, with the just in case system used for frequently ordered items. For inventory that is ordered infrequently, companies can rely on the just in time strategy.

TVI Logistics is ideally positioned to understanding the specific requirements of your business. To find out more about how TVI Logistics can assist your company with getting the competitive advantage over your rivals, subscribe to our email newsletter or contact us by filling in your details on our “Contact Us” page.